TMR Leftover collection

The 14th Five Year Plan for Industrial Green Development (referred to as the Plan) issued by the Ministry of Industry and Information Technology proposes that by 2025, China's energy efficiency will steadily improve, and the energy consumption per unit of added value of industrial enterprises above designated size will be reduced by 13.5%. In terms of agriculture, we will vigorously develop green and environmental protection equipment, accelerate the promotion and application of rural energy-saving and environmental protection equipment such as biomass gas supply, power supply, and agricultural film pollution control from crop straw and livestock manure.

Since 2020, many feed costs have been rising, especially for small and medium-sized pastures, which have been under significant cost pressure. Saving costs and increasing efficiency are urgent needs for herdsmen. The large amount of leftover materials accumulated during livestock and poultry breeding, if not effectively treated, can easily lead to resource waste. Collecting and reusing these leftover materials is an effective way to save feed costs.

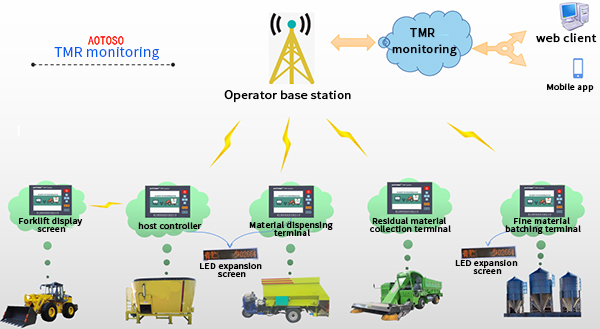

By installing TMR residual material collection terminals on the TMR residual material collection vehicles in the ranch, real-time recording of residual material collection information for each pen can be achieved. After uploading to the software platform, the remaining feed situation of the cow herd/pen can be analyzed to guide and supervise the feeding process of the cow.

Classic feeding overall solution architecture

The leftover material collection and monitoring system helps ranch users solve the problem of leftover material waste, save costs and increase efficiency, and improve users' economic benefits. The system mainly plans and develops the entire collection process, monitors the execution of the collection process, and conducts statistical analysis of the collection results.

This system consists of a cloud platform and a leftover material collection terminal (model: TMRLC001, 5G, cloud version), which can be linked with the TMR precision feeding monitoring system.